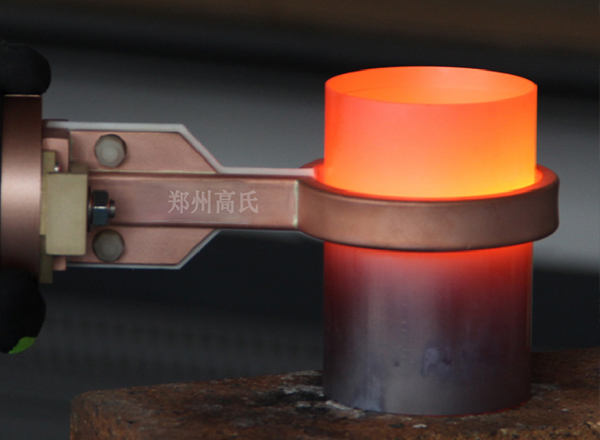

Zhengzhou Gou's induction heating equipment adopt IGBT technology, heating of the workpieces can be done segmentally and collectively in single and double station. By precise control of the entire workpiece heating requirements, the machine can greatly improve the performance and life of the workpiece. The induction heating machine is easy to install and operate, with reliable and flexible operating system. The inductor can be produced according to your special workpieces. Multi-Function with heating, hardening, brazing, annealing. Environmental protection, no noise, electric energy saving than traditional heating equipment.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200