Features of screw induction hardening equipment

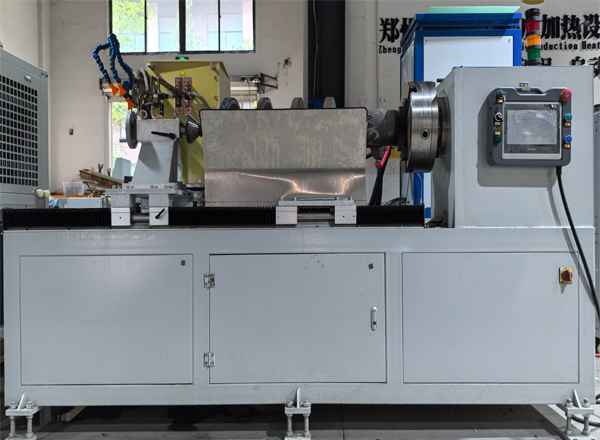

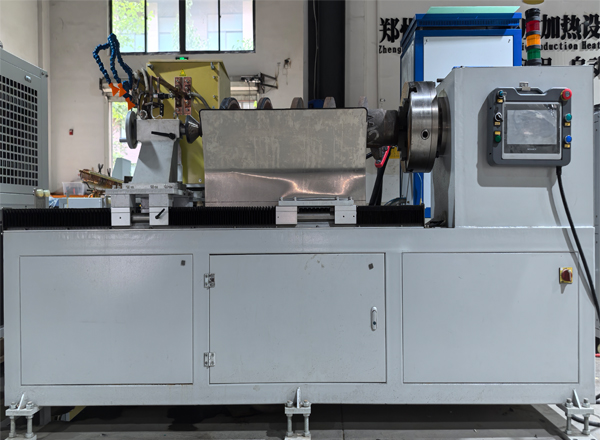

(I) Customized Design, Precisely Matching the Screw Structure. Unlike general-purpose hardening equipment, the core characteristic of screw hardening equipment lies in its high degree of customization. The equipment manufacturer will design the shape, number of turns, and magnetic field strength of the induction coil specifically based on the 3D drawings of the screw provided by the user (including parameters such as pitch, tooth profile, and lead), ensuring that the heating area perfectly corresponds to the critical stress points of the screw. For example, for the meshing tooth surface of a transmission screw, the coil will be designed with an arc-shaped structure that conforms to the tooth profile; for the helical surface of a conveying screw, the coil will adopt a spiral winding design to avoid "ineffective heating." At the same time, the equipment's tooling and fixtures will also be customized according to the structure of both ends of the screw (shaft head, flange, etc.), ensuring stable rotation of the screw during the hardening process and further improving heating uniformity.

(II) Intelligent Control, Simplifying Operation and Quality Control. Modern screw quenching equipment generally integrates intelligent control systems, possessing three core functions: First, parameter preset and storage: the quenching temperature, heating time, cooling speed, and other parameters for different specifications of screws can be stored as recipes, which can be directly recalled during subsequent processing, eliminating the need for repeated debugging. Operators can easily learn to use the system after simple training; Second, real-time monitoring and early warning: through infrared thermometers, current sensors, and other components, the system collects data such as heating temperature and coil current in real time. If any parameter is abnormal (such as temperature deviation or current fluctuation), the system will immediately alarm and automatically shut down to prevent the production of defective products; Third, data traceability: the equipment can record the quenching parameters and test results of each screw, forming a production log, which facilitates later quality traceability and process optimization.

(III) Low-temperature quenching process reduces workpiece deformation. As a precision component, controlling the deformation of the screw after quenching is crucial. Traditional high-temperature overall quenching easily leads to screw bending and reduced thread accuracy, requiring subsequent grinding and correction, which increases processing costs. The screw quenching equipment utilizes a low-temperature rapid quenching process, precisely controlling the heating rate (100-200℃/second) and cooling rate (50-100℃/second). This ensures surface hardness while reducing thermal stress and structural stress within the workpiece. In practical applications, the bending deformation of a 50mm diameter screw quenched with this equipment can be controlled within 0.1mm/m, far lower than the 0.5mm/m of traditional processes. In most cases, it can be directly assembled without subsequent correction, improving accuracy and reducing processing steps.

(IV) Safety and environmental protection are prioritized, and the equipment conforms to industrial standards. In terms of safety design, the equipment is equipped with multiple protection mechanisms: the electrical system is designed to prevent dust and oil contamination; the heating area is equipped with an infrared safety light curtain, which automatically cuts off the heating power when personnel approach; and the cooling system is equipped with a flow monitoring device to prevent coil burnout due to lack of water. In terms of environmental protection, the equipment does not require the use of coal, heavy oil, or other fuels, resulting in no exhaust emissions; the cooling medium mainly uses water-based quenching liquid, which can be recycled, resulting in minimal discharge; providing a safe and environmentally friendly working environment for workshop operators.

Advantages of screw induction hardening equipment

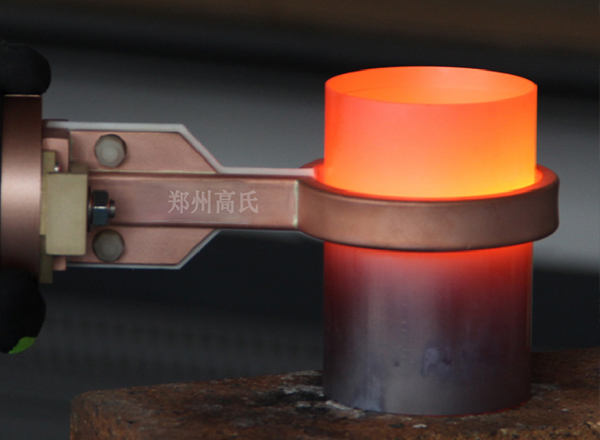

(I) Significantly improved processing efficiency and shortened production cycle. Traditional quenching processes often rely on overall heating or slow, segmented treatment, which not only requires long heating times but also multiple adjustments of tooling. The quenching cycle for a single screw often takes several hours. However, professional screw quenching equipment utilizes directional induction heating technology, precisely focusing on critical stress-bearing areas such as the screw threads and journals, achieving rapid localized heating. Typically, the target area can be heated to the quenching temperature (850-950℃) within 10-30 seconds, without waiting for the entire workpiece to heat up. Taking a conveying screw with a diameter of 50mm and a length of 1.2m as an example, traditional processes require 2-3 hours for quenching, while this equipment only takes 20-30 minutes, increasing the processing efficiency per screw by 6-8 times and significantly shortening the production cycle, making it particularly suitable for mass production.

(II) Ensuring uniform quenching quality and enhancing screw performance stability. The unique structure of the screw (intertwined threads, irregular surface) makes traditional quenching prone to "heating dead zones," resulting in insufficient local hardness or overheating, affecting reliability. The screw quenching equipment utilizes a multi-group induction coil adaptive adjustment design, which can adjust the magnetic field distribution in real time according to the screw's pitch and tooth profile parameters. This ensures uniform heating of the thread crests, roots, and sides. The hardness difference after quenching can be controlled within HRC 2, far lower than the HRC 5-8 difference of traditional processes. At the same time, the equipment's closed-loop temperature control system (accuracy ±5℃) prevents structural defects caused by temperature fluctuations, resulting in a uniform martensitic structure on the screw surface. This improves wear resistance by more than 30% and extends fatigue life by 2-3 times, effectively reducing fracture and wear failures during subsequent use.

(III) Reducing energy consumption and costs, and improving production efficiency. From an energy consumption perspective, traditional overall quenching requires heating the entire screw workpiece, resulting in significant heat loss, with unit energy consumption typically ranging from 800-1000 kWh/ton. In contrast, the localized heating method of the screw quenching equipment only works on the surface area requiring strengthening, reducing unit energy consumption to 300-400 kWh/ton, a reduction of over 50%. In terms of cost control, on the one hand, efficient processing reduces equipment usage time and labor input, lowering the processing cost per screw by 20%-30%. On the other hand, the modular induction coil design of the equipment allows for adaptation to different screw specifications (diameter 20-200mm, length 0.5-3m) by simply changing the coil, eliminating the need to customize equipment for each model. This significantly reduces equipment investment and maintenance costs, making it particularly suitable for companies with multi-variety, small-batch production.

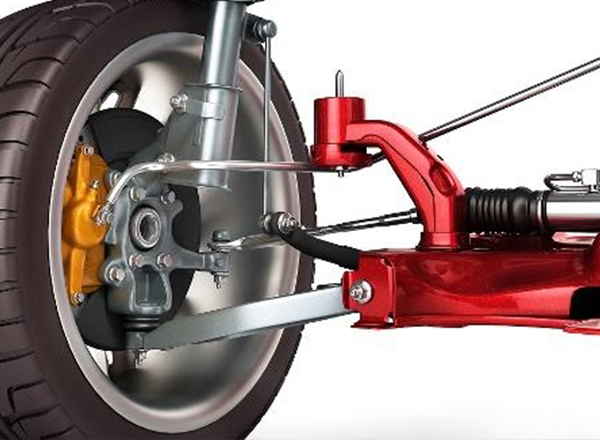

(IV) The screw hardening equipment possesses strong adaptability to various working conditions, meeting the specific needs of screws in different industries. For example, in the petrochemical industry, for screws transporting corrosive media, the equipment can utilize nitrogen-based protective atmosphere heating to prevent surface oxidation during the hardening process, thereby improving the corrosion resistance of the screws; in the automotive manufacturing industry, for gearbox screws requiring high precision, the equipment's servo positioning system can achieve a positioning accuracy of 0.02mm, ensuring that the hardened area perfectly matches the design requirements; in addition, the equipment supports integration into continuous production lines, forming a closed-loop production process of "feeding - hardening - cooling - discharging" through automated connection with feeding, cooling, and inspection stages. This adapts to large-scale assembly line operations in industries such as automotive, machinery, and building materials, further expanding its application scope.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200