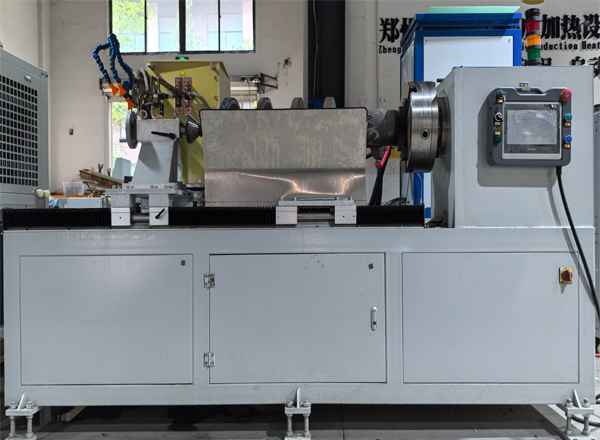

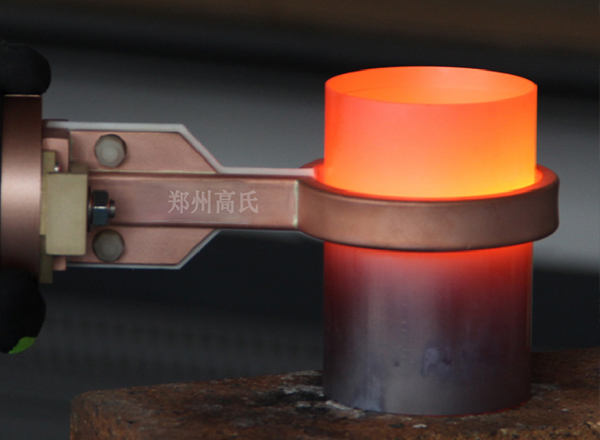

The hollow-shaft vertical induction hardening machine utilizes a large-screen LCD numerical control system, allowing for flexible programming and storage of various heat treatment process programs according to the process requirements of different workpieces. The vertical induction hardening machine offers precise control and a high degree of automation, resulting in consistent heat treatment results for workpieces. Workpiece rotation uses variable frequency stepless speed regulation, ensuring smooth and stable speed adjustment with minimal fluctuations. The machine bed of the vertical induction hardening machine is constructed from welded steel plates and undergoes overall stress relief treatment. It features standard linear guides. The aluminum alloy machine slide is corrosion-resistant and anti-magnetic. Heating positioning, water spraying, and time control are integrated into the machine's control system.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200