-

Products

- Medium Frequency Induction Heating Machine

- High Frequency Induction Heating Machine

- Ultrasonic Frequency Induction Heating Machine

- Ultra High Frequency Induction Heating Machine

- Special Ultrahigh Frequency Induction Heating Machine

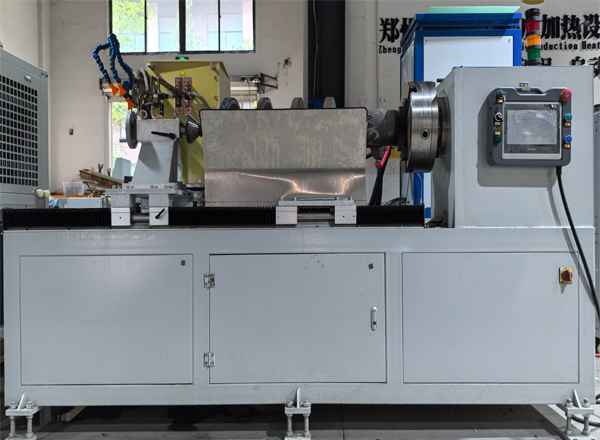

- Induction Hardening Machine Tool

- Handheld Induction Heating Machine

- Digital Induction Heating Machine

- Induction Heating Production Line

- Induction Melting Furnace

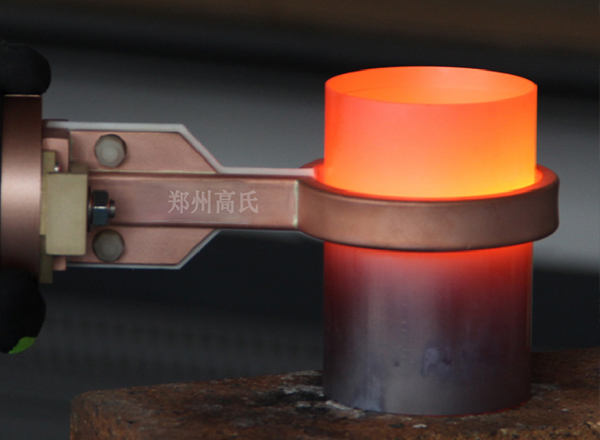

- Induction Heating Coil Customization

- Water Chiller

- Industries

- Applications

- Services

- About Us

- News

- Contact Us

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200