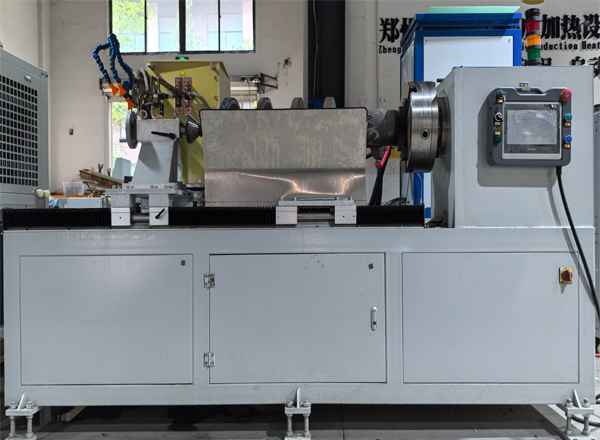

The Zhengzhou Gou's Electromagnetic LP-SK-2000 features a dual heating station, with two stations sharing a single power supply, allowing for alternating heating between the two stations. Part lifting and movement, as well as the induction sensor's feed movement, utilize linear guides, ball screw drives, and servo motor drives for precise position control. The length of the clamped part can be adjusted electrically. The spindle rotation is controlled by a variable frequency drive, allowing for stepless speed adjustment. The equipment consists of a vertical motion assembly, a workpiece rotating and clamping mechanism, an automatic feeding assembly, a water collection tank, a discharge system, an automatic quenching liquid spraying system, a pneumatic system, and a human-machine interface automatic control operating system. It features real-time variable movement speed and variable power supply capabilities.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200