Induction heating equipment, due to its high efficiency, energy saving, and precision, is suitable for processing various types of parts, especially in the fields of metal processing and heat treatment. Whether it's steel, aluminum alloys, or small parts with complex shapes, induction heating technology can provide excellent heating solutions. With continuous technological advancements, the application range of induction heating equipment will become even wider, providing more efficient support for the processing of various parts and driving the development of modern manufacturing.

Steel Components

Induction heating equipment is particularly suitable for processing steel components, such as shafts, gears, and other mechanical parts. Due to steel's excellent electrical and magnetic properties, induction heating can rapidly raise its temperature to achieve the desired heat treatment effect. This heating method not only provides uniform heating but also reduces deformation and stress.

Aluminum Alloy Components

Aluminum alloys, due to their lightweight and excellent thermal conductivity, are widely used in the aerospace, automotive, and electronics industries. Induction heating can effectively weld and heat-treat aluminum alloys, improving their strength and corrosion resistance. By precisely controlling heating time and temperature, overheating of aluminum alloys can be avoided, ensuring their performance.

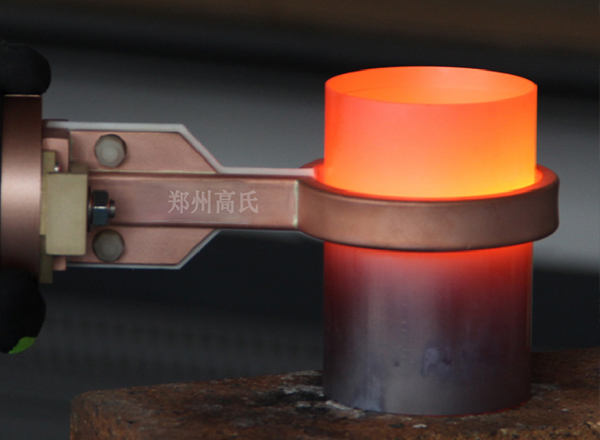

Complex-Shaped Components

Induction heating equipment can flexibly adapt to various complex-shaped components, including pipes, thin-walled parts, and irregularly shaped parts. Its heating method can target specific areas, avoiding the uneven heat distribution problems that may occur in traditional heating methods, improving heating efficiency and quality.

Small Components

For small components, such as screws, nuts, and other fasteners, induction heating equipment can achieve rapid heating, significantly reducing heating time and improving production efficiency. Furthermore, the precision of induction heating effectively prevents overheating, ensuring the quality and performance of components.

Welding Components

During the welding process, induction heating equipment can rapidly heat the welding area, ensuring the quality and strength of the weld. It is suitable for various welding processes, including spot welding, seam welding, and laser welding, effectively improving welding efficiency and reducing energy consumption.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200