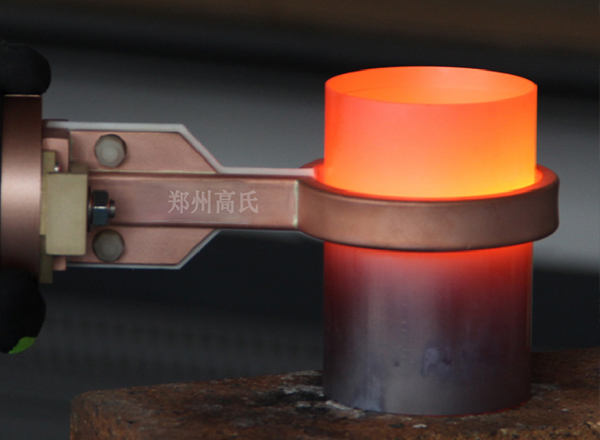

The induction hardening machines produced by Zhengzhou Gou's are widely used in automobile manufacturing, tractors and engineering machinery, machine tool manufacturing, heavy machinery, bearings, oil drilling rigs, metallurgical machinery, building materials and other industries. We have built our own factory for nearly 15 years, and our chief Engineer Ms. Gao and Mr. Gao have been engaged in quenching process research for more than 20 years and have provided good solutions to countless domestic and foreign customers. We not only produce induction hardening machines, but we can also customize vertical induction hardening machine tool and horizontal induction hardening machine tool according to customer requirements. What is more worth mentioning is that we have mature experience in quenching and tempering production lines. We welcome your inquiries, looking forward to your visit to the factory at any time.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl

GS-ZP-1200

GS-ZP-1200