For copper pipe welding, people used oxygen welding and argon arc welding in the past. Not only the welding effect is not satisfactory, but also the operation process is complicated, and a lot of manpower and material resources are wasted. With the continuous improvement of production technology, high-frequency induction welding machines are available. Once this equipment came out, it has been loved by many manufacturers due to its own unique advantages, and has become the first choice for copper pipe butt welding.

The high-frequency induction welding machine performs welding heat treatment on the copper tube, the heating speed is very fast, and the required temperature can be reached in a short time, which avoids the occurrence of oxidation and decarburization, and ensures the welding effect of the copper tube, so that after welding The high-quality copper pipe not only has firm and full welds, no missing welds and missing solder joints, but also has a very delicate appearance, basically no traces of welding can be seen.

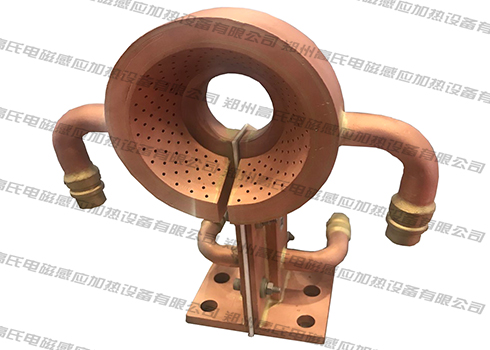

The high-frequency induction welding machine is highly efficient and energy-saving, and the heating is easy to control. The heating current value and heating voltage value can be set, and the current, voltage, power and frequency are all displayed. The operation is intuitive, simple and convenient. What's better is that when it performs welding heat treatment on copper pipes, the operation process is very simple. You only need to put the substrate and the object to be welded into the sensor to fix the position, and then start the equipment to heat up. No other operations are required. can be completed.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl