In the market, we will see a lot of stainless steel products, such as stainless steel bowls, stainless steel pots, stainless steel hangers, stainless steel guardrails and so on. Although common, few people pay attention or think about how these stainless steel products are formed. Anyone who understands its manufacturing process knows that the formation of stainless steel products requires many complicated processes. However, for our industry, how to ensure the smelting effect of stainless steel is the most important.

Smelting refers to the process of melting metal into crude metal or metal enrichment by heating, and the history of this process has been quite long. With the development of society, the equipment used for smelting is also undergoing earth-shaking changes, gradually transitioning from the original coal furnace and gas furnace to the medium frequency induction heating furnace heated by electricity.

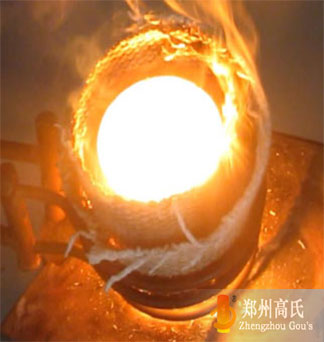

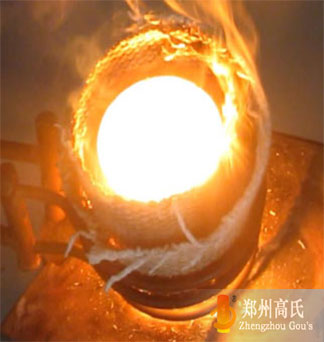

Stainless steel is smelted and heat-treated in a medium-frequency induction heating furnace. The heating speed is very fast, which avoids the occurrence of oxidation and decarburization, ensures the effect of smelting, and makes the smelted stainless steel free of impurities and floating dust, and even the purity is improved. Many, providing a reliable guarantee for the quality of stainless steel products. In order to make your operation more simple and intelligent, when your melting volume exceeds 10kg, we also recommend you to use a dumping furnace.

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl