Stainless steel is the abbreviation of stainless and acid-resistant steel. The steel grades that are resistant to weak corrosive media such as air, steam, and water, or have stainless properties are called stainless steel; The steel grade is called acid-resistant steel. Due to the difference in chemical composition between the two, the former is not necessarily resistant to chemical media corrosion, while the latter is generally stainless. The corrosion resistance of stainless steel depends on the alloying elements contained in the steel.

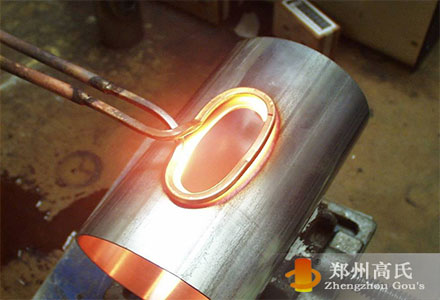

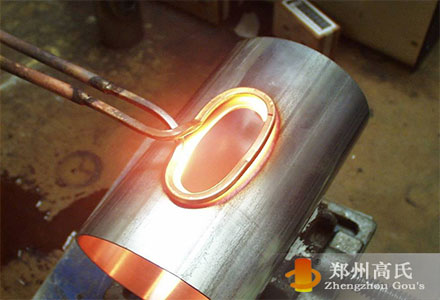

Because stainless steel itself has good corrosion resistance, stainless steel can still maintain its excellent physical and mechanical properties at high temperatures, and is widely used in all industrial fields and all aspects of daily life. Therefore, we use high-frequency induction annealing equipment to anneal stainless steel to eliminate its internal defects, refine the structure, reduce the surface hardness of the material, and facilitate subsequent processing.

The high-frequency induction annealing equipment uses electric heating, which will not produce noise and dust, and will not produce waste smoke and gas, which greatly improves the working environment of workers, enables workers to achieve environmentally friendly production, and provides health protection for workers. The high-frequency induction heating equipment can not only be used for annealing heat treatment of stainless steel, ribbed steel bars, wire rods, iron wires, aluminum tubes, etc., but also for gear quenching, half shaft quenching, bar heating, rivet thermoforming, and motor rotors. Hot loading, bearing hot dismantling, metal hot forming, etc. Therefore, choosing it will not let you suffer!

en

en  cn

cn  jp

jp  ko

ko  de

de  es

es  it

it  ru

ru  pt

pt  vi

vi  th

th  pl

pl